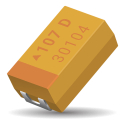

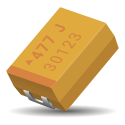

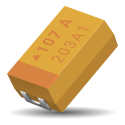

Surface Mount Capacitors for DC-DC Converter Applications Written By: Naotaka Hata Abstract: Tantalum, polymer, ceramic, film, and aluminum capacitors each offer a different set of operating and performance characteristics. Choosing the proper capacitor when designing DC-DC converters requires a careful understanding of these differences. High voltage front-end connections to the power source typically rely on aluminum capacitors, while intermediate step-down voltages often look towards the tantalum and ceramic families to take advantage of volumetric efficiency. The final load decoupling and bypass capacitors are generally found in the ceramic and film families. Surface mount (SMD) capacitors can be constructed using several different technologies to achieve a range of voltage tolerance, bulk capacitance, and parasitic device characteristics. As shown in Figure 1,

Tantalum / Niobium / Polymer

Radiation Tolerance of Tantalum Polymer Capacitors Written By: Krystof Adamek Abstract: Environments rich in ionizing radiation create a particularly difficult functional challenge for electronic components. Spacecraft, nuclear reactors, particle accelerators, and hardened military equipment (to name a few examples) demand that their electrical systems operate correctly, even in the presence of high energy particles, photons, electrons, neutrons, protons, and the like. Such radiation adversely affects electronics in two ways: fundamentally damaging the constituent materials, and creating transient electrical signals that can impede functionality. Mechanisms of radiation induced failure in semiconductors and other active devices have been well-studied, and methods for overcoming or preventing these failures have been developed. Passive devices like inductors, resistors, and capacitors, on the other hand, are

Failure Mode Comparison of Tantalum and Niobium Oxide Capacitors Written By: George Zhang Abstract: The automotive industry has become highly dependent on advanced sensing and computing. Starting in the mid-twentieth century, the development of dense, reliable, and stable capacitors has been instrumental in advancing high speed computing and high performance electronics. The demands on these capacitors have increased substantially, requiring high-temperature tolerance, harsh environmental reliability, and ever-decreasing parasitic parameters such as equivalent series resistance (ESR) and inductance (ESL). Tantalum and niobium oxide capacitors have been two of the most notable contenders to meet these requirements. Though similar in construction, their failure modes are nuanced and require a careful understanding to ensure a successful design for a particular application.

Tantalum Capacitors for Electric Vehicles Written By: Jeff Lee Abstract: An electric vehicle is a car powered by electricity unlike internal combustion locomotives that obtain driving energy by burning fossil fuels, they rotate the motor with electricity accumulated in the battery to obtain driving energy. Electric vehicles are largely composed of on-board chargers (OBC), electric power control units (EPCUs), motors, speed reducers, and high voltage battery. The motor of an electric vehicle is a high-efficiency and high-power driving motor and has high output and rotational power. Unlike internal combustion vehicle engines, the electric motor can be made to minimize noise and vibration generation while driving.

Polymer Solid Electrolytic Capacitors for Automotive Applications Written By: Jaroslav Tomasko | Slavomir Pala Abstract: Tantalum electrolytic capacitors are constructed using a sintered pellet of powdered tantalum as the anode of the device. A grown oxide layer on the contoured surface of the pellet acts as the dielectric insulator, and a cathode terminal is formed using either a conventional MnO2 electrolyte or a conductive polymer to sufficiently contact the oxide layer. The final capacitor can be packaged in many forms, and the typical J-lead surface mount construction is shown in Figure 2. The capacitive structure is bonded to a molded case and electrically interfaced using carbon as a separation layer and silver for connection with the lead frame.

Analysis of the DC Blocking Capacitor for Stereo High-Fidelity Audio Written By: Rick Liu Abstract: The representation of audio signals in analog and digital electronics can take many forms. Still, they must ultimately be converted back to their mechanical origins as the motion of air molecules propagating as waves. These waves are generated by moving a mass, often the cone of a speaker, back and forth around a neutral position. As such, any fixed offset in the audio signal, represented by a DC bias, is simply a waste of energy and possibly a source of imbalance in the resulting sound wave. Series blocking capacitors are generally used for each audio channel to eliminate the potential of any DC component. While

Tantalum Capacitors in 5G Smartphone Applications Written By: Jason Liu Abstract: The global smartphone market has grown enormously over the past decade. In 2019, about 1.32 billion smartphones were shipped globally, of which 367 million units were shipped in China alone, accounting for 27.8% of the global total. With the ongoing investment into the construction of 5G networks, especially in China, 5G-enabled smartphones are set to become ubiquitous in the near future. 5G phones are projected to grow by 10% starting in 2020 compared to the previous year. Under favorable economic and regulatory conditions, there will be ample opportunities for both leading and emerging manufacturers to capture more market share. Additionally, there are several design houses for smartphones that design

Replacing Aluminum Electrolytic Capacitors with Tantalum or Ceramic Capacitors Written By: Teddy Won Abstract: Like all capacitors, electrolytics (e-caps) are based on the principle of storing energy in an electric field using a voltage applied across a dielectric. This paper discusses the basic structure and characteristics of electrolytics and shows alternates for circuit use.

Low ESR Tantalum Capacitors in Circuit Design Written By: Colin Li Abstract: Tantalum is a relatively scarce transition metal with several unique properties that make it a technology-critical element. It is highly corrosion-resistant and chemically inert. It is non-ferrous and non-magnetic, has a high melting point and density, and is extremely stiff. Most importantly, Tantalum readily forms a protective and electrically insulating oxide layer. This ability makes it an ideal candidate as the base building block of electrolytic capacitors.

Tantalum and SuperCapacitors Enable Maintenance Free Microcontrollers Written By: Ron Demcko | Daniel West | Ashley Stanziola Abstract: Ultra-low-power microcontroller families now exist with such low power requirements that they can be powered by energy harvesting rather than battery-operated or conventional mains. These powerful MCUs enable maintenance-free control systems in applications ranging from structure/soil/water/air monitoring applications to industrial point controllers (such as smart faucets) to wearable electronics, location tracking, and even BLE beacons.

Tantalum Capacitors: Characteristics and Component Selection Written By: Raul Wang Abstract: Capacitors are one of the fundamental building blocks of electrical circuits. Whether they are being used for energy storage, noise filtering, or timing/frequency design, capacitors are important in many common electrical devices. Today, various capacitor technologies are available, each with their own unique benefits and drawbacks, making each type ideal for different applications. Tantalum capacitors offer many interesting characteristics that combine to offer a unique solution to many design problems.

Tantalum Polymer vs Aluminum Polymer Performance as an Output Filter Capacitor for Miniature Switching Power Supplies Written By: Ron Demcko | Ashley Stanziola | Daniel West Abstract: Engineers have questioned the impact performance of converting Aluminum Polymer capacitors to Tantalum Polymer capacitors in applications where MLCCs are present on the output filter ‘bank’ of a small switching power supply. The reasons for designers to convert to Tantalum Polymer capacitors in the design ranged from long term reliability and stability to availability/delivery and company specific design guidelines. This investigation is intended to compare the interchangeability of Tantalum Polymer Capacitors in a design with the original Aluminum Polymer capacitors. The data collected was the measured output voltage ripple on a highly utilized

Solid tantalum capacitors have a long history of proven performance in high-reliability military and space applications. But not all capacitors are created equal — even within the same class. As is the case with virtually all component technologies, materials matter. This paper will discuss the differences in performance and reliability between solid tantalum capacitors with manganese dioxide (MnO2) cathodes and those with conductive polymer cathodes. Bell Laboratories introduced the first solid tantalum capacitors to market in the early 1950s. The first military specification for surface-mount tantalum capacitors (MIL-PRF-55365) was released in 1989 and introduced CWR09-style components. Since then, the product offerings governed by this specification have expanded to include CWR19-style capacitors with an extended range of CV values and CWR29-style

MLCC & TANTALUMINTERCHANGEABILITY Tantalum chip and Hi CV MLCC have a large degree of overlap in available capacitance ratings in common footprints. As MLCC production increased, many applications converted from tantalum to MLCC for many filtering, bypass, and hold-up applications. With the increasing demands seen for low voltage digital applications, tantalum electrolytic technologies have become a first choice for MLCC substitution. KYOCERA AVX is a leading international manufacturer and supplier of a wide range of advanced electronic components, including: capacitors, inductors, filters, and circuit protection devices. The KYOCERA AVX tantalum electrolytic division has maintained a leadership position in automotive, industrial, medical, space, military, consumer electronics, communications, and transportation markets for nearly 50 years. Maximum Available Capacitance by Case Size (6.3V):

Temperature Stability Assessment of GaN Power Amplifiers with Matching Tantalum Capacitors Written By: Ron Demcko | Mitch Weaver | Daniel West Abstract: Wide band gap GaN and SiC devices are expected to experience high levels of growth in applications ranging from power conversion to RF transistors and MMICs. End users recognize the advantages of GaN technology as an ability to operate under higher currents and voltages. RF GaN market is expected to grow at 22.9 % CAGR over 2017-2023, boosted by implementation of 5G networks. [1] During the past years, the wide band semiconductors have reported achievement of >1000 V BDV that opens new challenges for high power industrial applications such as electric traction systems in trams, trolley buses or

High-Reliability Solid Tantalum Capacitors Bob Fairey AVX Corporation, One AVX Blvd, Fountain Inn, SC 29644www.avx.com Solid tantalum capacitors are among the most popular types of small, surface-mount capacitors for electronic applications across the consumer, automotive, aerospace, and medical device markets. This paper will provide some context on the development of tantalum capacitor technology and address issues frequently faced by users, including the need for low equivalent series resistance (ESR) in filtering applications and the need for the highest possible reliability and long-lifetime performance in aerospace and medical applications. Figure 2: The dielectric surface area of a tantalum capacitor anode compared to its finished size. Over the course of the following decades, tantalum capacitor technology evolved to include several form factors.